Scientists make robots that can walk straight out of the printers that created them

Researchers said the new devices are a ‘game-changer’

Scientists have achieved a breakthrough in soft robotics, creating four-legged robots capable of walking immediately after being 3D-printed. This innovation utilizes a novel upside-down printing method, paving the way for scalable production of flexible devices.

Soft machines, constructed from pliable materials like soft plastics, hold immense promise for various applications, including nuclear decommissioning, biomedicine, and space exploration. However, the lack of standardized design and scalable manufacturing has hindered their widespread adoption, presenting both technical and financial obstacles.

This new 3D printing system addresses these challenges, potentially revolutionizing the field of soft robotics.

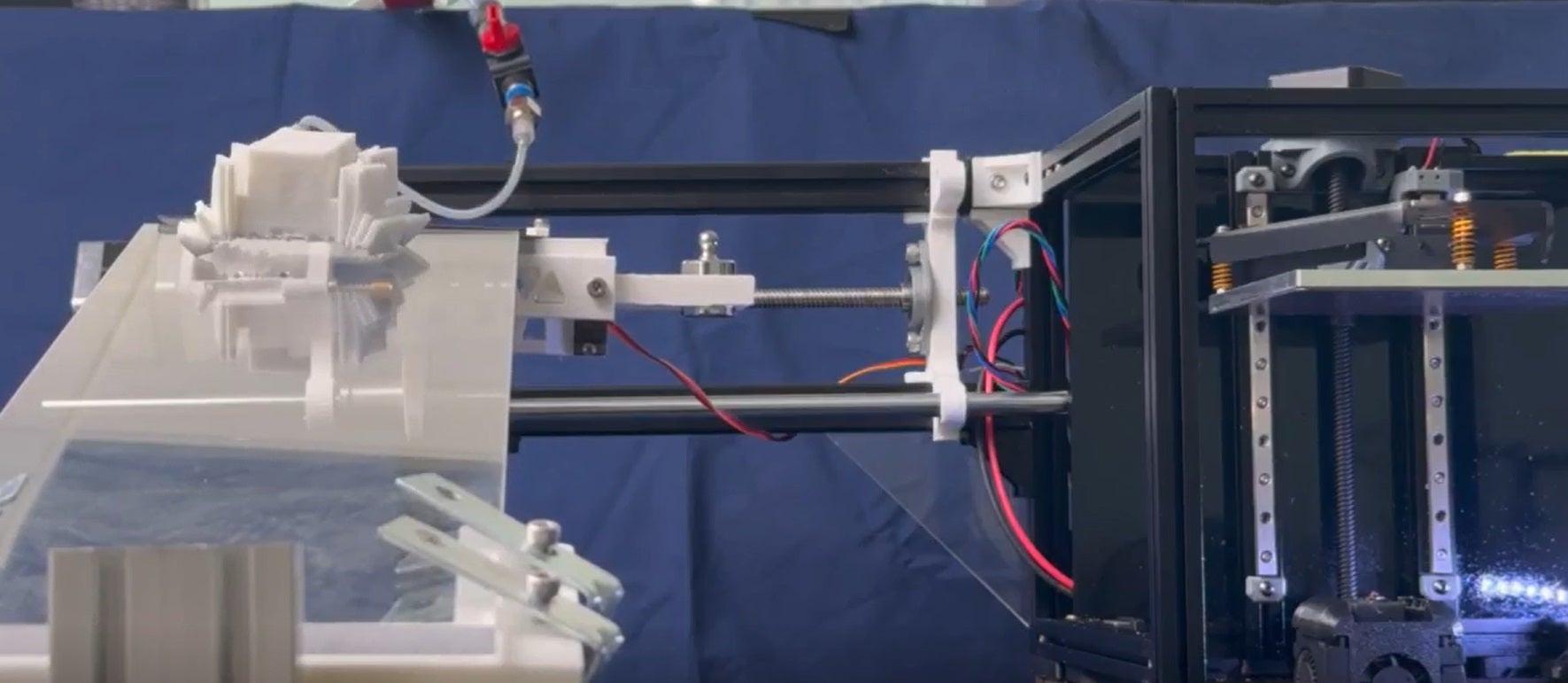

The Edinburgh University team from sought to overcome these challenges by developing a low-cost, desktop 3D printing system for creating soft robots.

Their user-friendly setup can be assembled for under £400 using off-the-shelf parts.

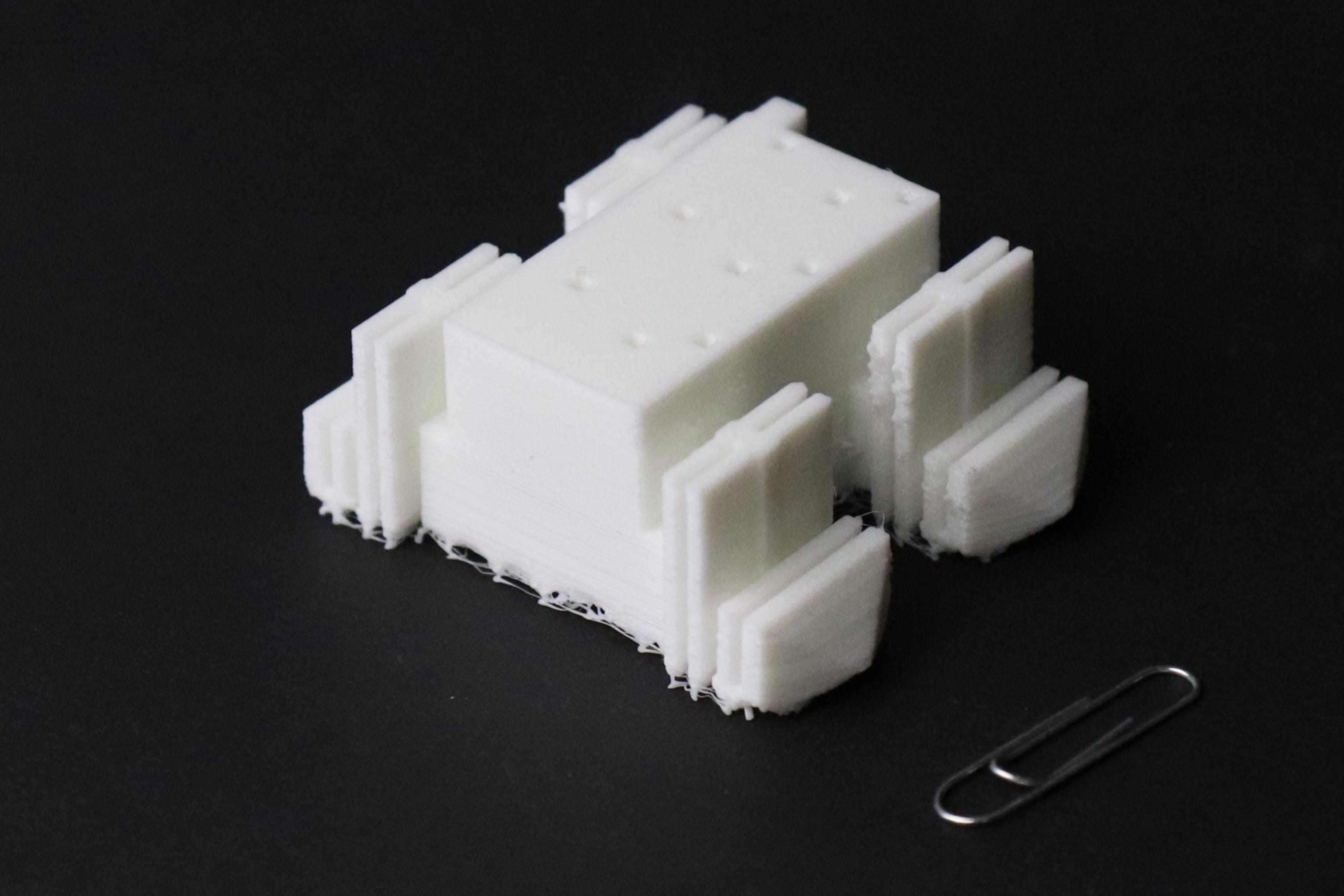

The team demonstrated the capabilities of their new system by creating robots made from a soft plastic material and powered by air pressure.

Once printed, the robots are connected to a compressed air supply before walking out of the machine on which they were made.

The researchers believe this could pave the way for the use of intelligent soft robotic systems with no electronic parts.

Lead engineer on the project, Maks Gepner, said: “It used to take years to figure out how to print using these materials.

“Using our new platform, anyone can now easily print things which were previously thought to be impossible.

“This is a game-changer for engineers and artists alike.

“Our hope is that this technology will help drive the next wave of research breakthroughs.

“Without the long-standing manufacturing and design bottlenecks holding it back, we believe soft robotics is ready to make a major real-world impact.”

Mr Gepner was supported on the project by fellow PhD student at the Centre for Doctoral Training in Robotics and Autonomous Systems, Jonah Mack, and lead academic Professor Adam A Stokes, head of the university’s Institute for Bioengineering.

Building and operating their new system – known as the Flex Printer – requires little prior knowledge, with first-time users able to assemble it and begin making robots in just a few days, the team said.

They have made their designs publicly available to broaden access to soft robotic technologies and to help foster collaboration and improvements to the system.

The findings are published in the journal Device. The research was funded by the Engineering and Physical Sciences Research Council.